Side Flexing Flexible Chains 63 70 mm FT70

Material: POM Acetal (LF White Low Friction), Cold Rolled Austenitic Stainless Steel Pin, Standard Aluminium Beam

Main Application: Conveying lines for PET bottles, yogurt, tissue paper, aluminium or steel cans, lines packages

Max Speed: 80m/min lubricated, 50m/min dry

Max Conveyor Length: 40m, Work Load.: 900N

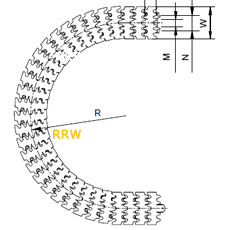

Min Radius: Chain 63 R 150 , Chain 70 R 200

* Side Flexing Flexible Chains 63 is based on 65 mm (70 based on 72 mm wide) conveyor beams in aluminum or stainless steel, wide applications for pallet handling, vertical conveyors, tissue paper, aerosol cans, plastic bottles, matches, cheese boxes, coffee tea packages

* Multi-flexing plastic flexible chains are widely used in conveyor system for transport, product buffering accumulation, PCB assembly line, paper converting, elevating, diverting, collating products, packs, packaging and filling line, conveyor for cosmetic bottles, etc.

| Chain Code | Chain Pitch(mm) | Chain Width(mm) | Beam Width(mm) | Tension(N) |

|---|---|---|---|---|

| Chain 63 | 25.4 | 63.0 | 65 | 900 |

| Chain FT70 | 25.0 | 70.0 | 72 | 1000 |

| 82.6 R150 | 31.75 | 82.6 | 84 | 1250 |

| Chain 82.6 | 33.5 | 82.0 | 84 | 1250 |

| Chain 83 | 37.6 | 83.0 | 85 | 1250 |

| Chain 103 | 37.6 | 103.0 | 105 | 1250 |

| Chain 146 | 36.0 | 146.0 | 148 | 1250 |

Side Flexing Flexible Chains FT70 70 mm Multi-flexing Conveyor Chains

Drive Gear Sprockets for Flexible Chains 63 70 mm

Processing: Milling Machined (White), Plastic Injection (Black)

Material: Nylon PA6, Machined Split or Molded Split, Keyways

Teeth No.: 8, 9, 10, 11, 16

Bore Dia.: 20, 25, 30, 35, 40 (Shaft Sized Bore / Plain Bore)