Plastic Belt Table Top Slat Chains Sprockets Idlers Conveyors

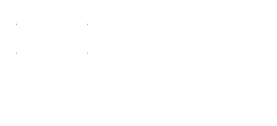

Material: POM Acetal / Nylon PA6, Milling Machined or Plastic Molded Injection, Keyways

Sprocket Bore Dia.: P20, 25, 30, 35, 40 Sprocket Teeth No.: 9, 11, 15, 17, 19, 21, 23, 25

Applications: Food and Beverage Conveyor Lines Drive for PET bottles, Aluminum or Steel Cans, Packaging Lines, Oil Filling Lines, Pharmaceutical Pharmaceutics Manufacturing

* 820/821, 880/882 Plastic Table Top Chain Drive Sprocket Conveyor

* SS 802/812/881 Steel Table Top Chain Conveyor Drive Sprocket

* Modular Chain Belt Table Top Slat Chains Sprockets Drive Conveyor

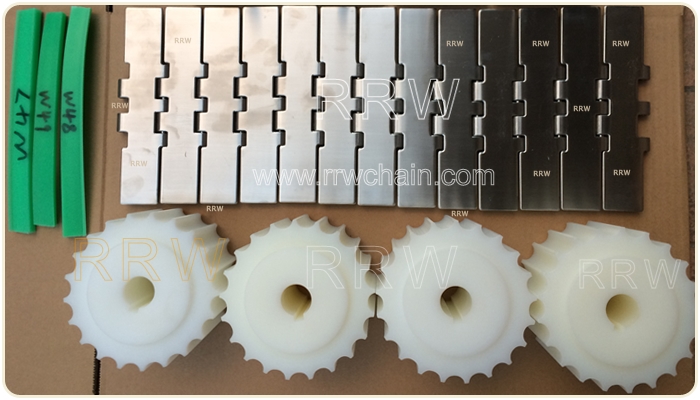

The Table Top Chain Conveyor System is Consisted of Slat Top Chains, Gear Motors, Table Top Slat Chains Sprockets, and assembled with Tube Support Legs, Guide Brackets Profiles, Wear Strips, Chain Tracks, etc. The system is running in low friction and co-efficient, which would be ideal solution for you production line transmission.

* The Conveyors are widely used in Automatic Lines for Food Beverages, Dairy and Milk, Beer, Edible Olive Oil Packaging, Agriculture, Fruits Washing Sorting and Grading

* The Chain conveyors are also solutions for Packaging Machinery conveying, Labeling, Bottling Canning Filling, Crate Carton Filling, Empty Keg Lines and Case Conveyors, Low Back Pressure Chains for Products Table Accumulation etc.

* The Modular Chain Belt Conveyors are assembled of Flat Top Belts, Flush Grid Belts, Raised Rib Top Belts, Rubber Top Belts, Table Top Chains, Rubber Top Chains. This Modular Conveyor is Capable for Large Size Production Line Handling and Wider Radius Operation